aluminium cutting machine

Home » aluminium cutting machine

aluminium cutting machine in dubai

aluminium cutting machine: Enhancing Precision and Efficiency at Sakher Workshop in Dubai

aluminium cutting machine

Table of Contents

Aluminium Cutting Machine in Dubai

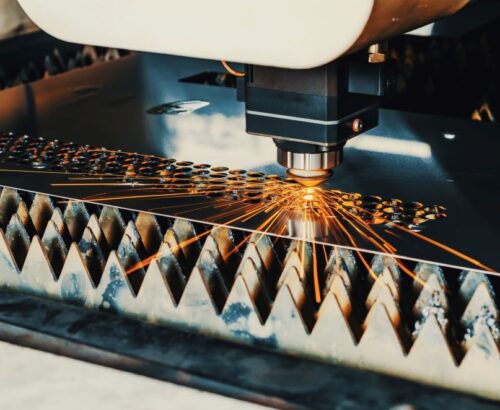

aluminium cutting machine In the world of metal fabrication, precision and efficiency are paramount. When it comes to cutting aluminum, traditional methods often fall short in meeting the demands of modern industries. However, thanks to advancements in technology, aluminum laser cutting has emerged as a game-changer. One notable workshop that has embraced this cutting-edge technique is Sakher Workshop in Dubai. In this article, we will explore the benefits of aluminum laser cutting and how Sakher Workshop has become a leader in this field.

The Advantages of aluminium cutting machine

1. Unparalleled Precision

Aluminum laser cutting offers unparalleled precision compared to conventional cutting methods. The laser beam can be precisely controlled to cut through aluminum with incredible accuracy, resulting in clean and precise cuts. This level of precision is crucial in industries where even the slightest deviation can lead to significant consequences.

2. Versatility in Design

With aluminum laser cutting, the possibilities for design are virtually limitless. The laser beam can be programmed to cut intricate shapes and patterns, allowing for the creation of complex and aesthetically pleasing designs. Whether it’s for architectural elements, automotive parts, or aerospace components, aluminum laser cutting offers the flexibility to bring any design concept to life.

3. Enhanced Efficiency

Compared to traditional cutting methods, aluminum laser cutting offers enhanced efficiency. The laser beam cuts through aluminum at a rapid pace, significantly reducing production time. Additionally, the precision of the laser ensures minimal material wastage, optimizing resource utilization and reducing costs.

4. Clean and Burr-Free Cuts

One of the key advantages of aluminum laser cutting is its ability to produce clean and burr-free cuts. Unlike traditional cutting methods that often result in rough edges and burrs, the laser beam melts and vaporizes the aluminum, leaving behind smooth and flawless edges. This eliminates the need for additional finishing processes, saving both time and money.

5. Non-Contact Cutting

Aluminum laser cutting is a non-contact cutting method, which means that the laser beam does not physically touch the material being cut. This eliminates the risk of material deformation or damage that can occur with traditional cutting methods. Non-contact cutting also allows for the cutting of delicate and thin aluminum sheets without the risk of warping or distortion.

Sakher Workshop: Leading the Way in Aluminum Laser Cutting

Located in the vibrant city of Dubai, Sakher Workshop has established itself as a leader in aluminum laser cutting. With state-of-the-a

rt equipment and a team of highly skilled technicians, Sakher Workshop offers a wide range of aluminum cutting services tailored to meet the unique needs of its clients.

aluminium cutting machine in dubai

Services Offered by Sakher Workshop

1. Custom Aluminum Laser Cutting

Sakher Workshop specializes in custom aluminum laser cutting, catering to vario

us industries such as construction, automotive, and aerospace. Their team of experts works closely with clients to understand their specific requirements and deliver precise and high-quality cuts.

2. Prototyping and Design Assistance

In addition to aluminum laser cutting, Sakher Workshop provides prototyping and design assistance serv

ices. Their experienced team can help clients transform their design concepts into functional prototypes, ensuring that every detail is meticulously executed.

3. Large-Scale Production

Sakher Workshop has the capacity to handle large-scale production projects. With their advanced laser cutting machines and efficient workflow, they can meet tight deadlines without compromising on quality. Whether it’s a small batch or a high-volume production run, Sakher Workshop has the capabilities to deliver.

4. Material Selection and Optimization

Choosing the right aluminum alloy for a specific application is crucial. Sakher Workshop offers material selection and optimization services, guiding clients in selecting

the most suitable aluminum alloy for their project. This ensures optimal performance and longevity of the finished product.

5. Quality Assurance

At Sakher Workshop, quality is of utmost importan

ce. They have implemented a rigorous quality assurance process to ensure that every cut meets the highest standards. From initial design to final inspection, Sakher Workshop maintains strict quality control at every stage of the aluminum laser cutting process.

Aluminium Cutting Machine in Dubai

Frequently Asked Questions (FAQ)

1. How does aluminum laser cutting compare to other cutting methods?

Aluminum laser cutting offers superior precision, versatility, and efficiency compared to traditional cutting methods such as sawing or shearing. The laser beam can cut through aluminum with incredible accuracy, allowing for intricate designs and clean cuts.

2. Is aluminum laser cutting suitable for all types of aluminum alloys?

Yes, aluminum laser cutting is suitable for a wide range of aluminum alloys. Sakher Workshop offers material selection and optimization services to help clients choose the most appropriate alloy for their specific application.

3. Can aluminum laser cutting be used for both small-scale and large-scale production?

Absolutely! Sakher Workshop has the capacity to handle both small-scale and large-scale production projects. Their advanced laser cuttingmachines and efficient workflow allow them to meet the demands of various production volumes.

4. Are there any limitations to aluminum laser cutting?

While aluminum laser cutting offers numerous benefits, there are a few limitations to consider. Thicker aluminum sheets may require multiple passes to achieve the desired cut, which can increase production time. Additionally, highly reflective aluminum surfaces may absorb less laser energy, requiring adjustments in laser power settings.

5. How can I request a quote or get in touch with Sakher Workshop?

To request a quote or get in touch with Sakher Workshop, you can visit their website at www.sakher.ae or contact their customer service team at +971 54 507 0071 They will be more than happy to assist you with any inquiries or project requirements.

Aluminum laser cutting has revolutionized the metal fabrication industry, offering unparalleled precision, versatility, and efficiency. Sakher Workshop in Dubai has embraced this cutting-edge technology, positioning themselves as leaders in the field. With their expertise in custom aluminum laser cutting, prototyping, large-scale production, and quality assurance, Sakher Workshop is the go-to destination for all aluminum cutting needs. Whether it’s for architectural projects, automotive components, or aerospace applications, Sakher Workshop delivers exceptional results that exceed expectations. Contact them today to experience the power of aluminum laser cutting at its finest.