Laser Metal Cutting Services

Laser Metal Cutting Services In Dubai

Sakher Engineering offers Laser Metal Cutting Services laser metal cutting in stainless steel,aluminum copper, brass, bronze, and nickel/chrome, thickness from 0.02mm through 1.0Cm

Metal

Carbon Steel – DC01

Carbon Steel – DD11

Finishes

Natural – Vibrated – Sandblasting

Thicknesses

■ 1 mm ■ 1.2 mm ■ 1.5 mm

■ 2 mm ■ 3 mm ■ 4 mm

■ 5 mm ■ 6 mm ■ 7 mm ■ 8 mm ■ 9 mm ■ 10 mm ■ 11 mm ■ 12 mm

It stands out for its ease

cold-forming. Attracted by magnets and low-cost, perfect for painting.metal

Galvanized Metal

Galvanized steel DX51 Z275

Finishes

Natural

Thicknesses

■ 1 mm ■ 1.2 mm ■ 1.5 mm

■ 5 mm ■ 6 mm ■ 7 mm ■ 8 mm ■ 9 mm ■ 10 mm ■ 11 mm ■ 12 mm

With galvanized factory-coating, it ensures

a good environmental resistance without the need for surface treatments.

Chrome Stainless Steel

Stainless Steel 304

Stainless Steel 316

Finishes

Natural – Vibrated – Brushed – Shiny – Sandblasted

Thicknesses

■ 0.5 mm ■ 1 mm ■ 1.2 mm

■ 1.5 mm ■ 2 mm ■ 3 mm

■ 4 mm ■ 5 mm ■ 6 mm

■ 7 mm ■ 8 mm ■ 9 mm ■ 10 mm ■ 11 mm ■ 12 mm

The most versatile material, with high

mechanical performance, ready for outdoor applications and super aesthetic.

Copper Metal

Copper – DHP

Finishes

Natural – Vibrated – Brushed – Shiny – Sandblasted

Thicknesses

■ 1.2 mm ■ 1.5 mm ■ 3 mm

Unmistakable reddish appearance, perfect electrical

conductor and malleable. Perfect for both technical and decorative applications.

Brass – CuZn37

Finishes

Natural – Vibrated- Brushed – Shiny – Sandblasted

Thicknesses

■ 1.2 mm ■ 1.5 mm ■ 3 mm

Aluminum

Aluminum 5754

Finishes

Natural – Vibrated – Brushed – Sandblasted

Thicknesses

■ 1 mm ■ 1.2 mm ■ 1.5 mm

■ 2 mm ■ 3 mm ■ 4 mm

■ 5 mm ■ 6 mm ■ 8 mm

The metal is known for its low

density and outstanding mechanical qualities. Perfect for drilling or cold forming.Aluminum

Laser Metal Cutting : Crafting Excellence in Metal and Acrylic

In the ever-evolving world of precision manufacturing, laser cutting technology has emerged as a game-changer. Laser metal cutting services have gained immense popularity for their ability to shape metal and acrylic with unparalleled precision. In this article, we will delve into the world of laser metal cutting services, exploring their applications, advantages, and how they are transforming industries.

Laser Metal Cutting

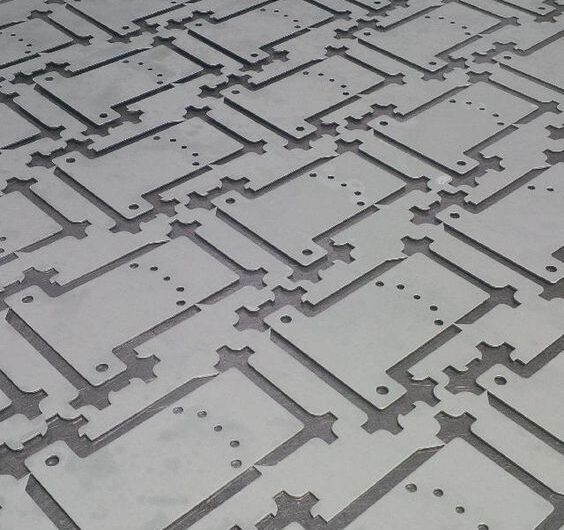

Laser metal cutting is a cutting-edge process that employs high-powered laser beams to precisely cut and shape metal sheets. This technology offers a level of precision and intricacy that traditional cutting methods cannot match.

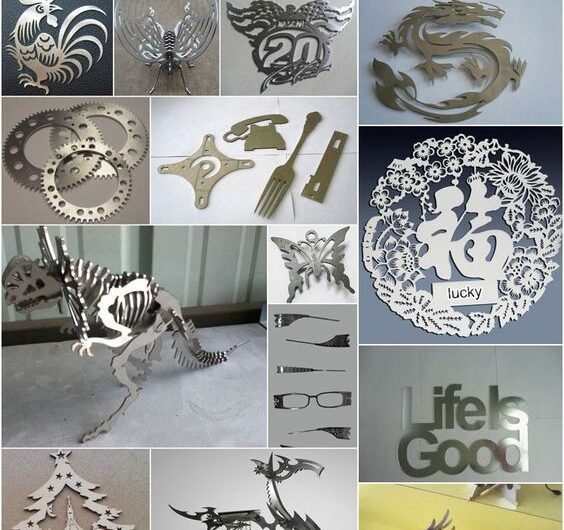

Applications of Laser Metal Cutting

Sheet Metal Fabrication: Industries like aerospace, automotive, and construction rely on laser cutting for intricate sheet metal components used in various applications.

Custom Metal Art: Artists and designers utilize laser metal cutting to create intricate metal art pieces, sculptures, and decorative items.

Industrial Prototyping: Laser cutting enables the rapid and precise prototyping of metal parts, speeding up product development.

Architectural Elements: Laser-cut metal is used to craft intricate architectural details, adding a touch of sophistication to buildings and structures.

The Versatility of Laser Acrylic Cutting

Exploring Laser Acrylic Cutting

Laser acrylic cutting is an art in itself, where laser technology is employed to cut and shape acrylic sheets with exceptional precision. This process opens up a world of possibilities in design and fabrication.

Applications of Laser Acrylic Cutting

Custom Signage: Laser acrylic cutting produces flawless signage with sharp edges and intricate designs, making it a popular choice for businesses.

Personalized Displays: Retailers use laser-cut acrylic for creating eye-catching displays, which can be customized to showcase products effectively.

Architectural Models: Architects and model makers use laser-cut acrylic to craft intricate architectural models that help visualize building designs.

Prototyping and Jewelry: Laser acrylic cutting is also used in jewelry making and rapid prototyping due to its precision.

Advantages of Laser Metal and Acrylic Cutting Services

1. Precision and Intricacy

Laser cutting offers unmatched precision and the ability to create intricate designs with fine details, ensuring a high level of accuracy in every cut.

2. Speed and Efficiency

The speed and efficiency of laser cutting technology enable rapid production of parts and products, reducing lead times and increasing productivity.

3. Versatility and Customization

Laser cutting services cater to a wide range of materials and designs, allowing for extensive customization to meet specific project requirements.

4. Minimal Material Waste

Laser cutting minimizes material waste by optimizing the cutting process, making it an environmentally friendly option.

Laser metal cutting services have revolutionized the manufacturing industry by providing unmatched precision and versatility. From aerospace components to intricate metal art, they have left their mark on a wide range of applications. Similarly, laser acrylic cutting services have unlocked new dimensions in design, enabling the creation of intricate signage, displays, and architectural models.

For businesses and individuals seeking precision cutting services, laser cutting workshops are the go-to choice. They offer the expertise and technology needed to turn designs into reality with impeccable precision. In the world of precision cutting, laser technology continues to shine brightly, shaping the future of manufacturing.

Access Now: Laser Metal and Acrylic Cutting Services